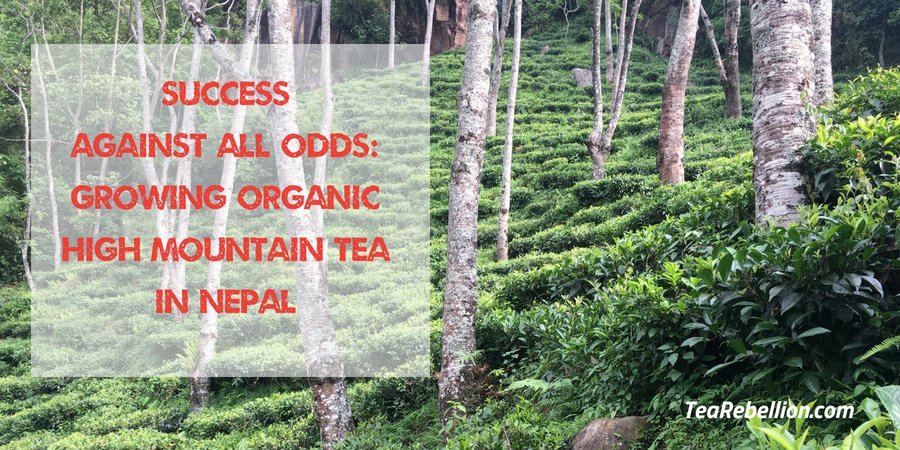

Success Against all Odds: Growing organic High Mountain Tea in Nepal

Nepal has experienced complex political, democratic and social challenges (think caste system) that have evolved over the past 30 years. Upon our arrival, we had to quickly absorb the recent political history and turmoil the country has endured since before and after the tragic massacre of the royal family and King Birendra in June 2001. Despite the chaos and ridiculously frequent political leadership changes, there are amazing stories of social change and transformation happening in this country. The story of Kanchanjangha Cooperative set in the far East of the country is one such story…

How it all began:

Young Deepak Prakash grew up in a high mountain community in the Panchthar district (close to Phidim) and was 15 years old when he visited Darjeeling, India. The flourishing tea plantations and sustainable livelihoods they created planted a seed of inspiration in him. Upon his return home, his vision was to build a tea garden high up in the Himalayas with high quality teas, unique to Nepal. The biggest challenge to this vision? His youth did not command the respect he required to gain support. However, he was no quitter and he convinced his friends to plant tea bushes in his backyard. When they flourished after a few years, others happily followed suit and from here, a new vision was born. The vision: Pooling the lands and creating a sizeable tea cooperative where each member had voting rights.

Making it happen:

The challenges to realizing the vision and convincing others that it would be plentiful?

- Topography

- Finances: there was no money to build a factory

- Infrastructure: there was no road to transport the leaves

One by one they overcame these challenges. How so?

- Fundraising

- When engineers told the Cooperative that the road could not be built, members constructed it themselves.

- They even created a school for all the cooperative members kids down in Phidim!

Over time, the Cooperatives technical tea “know how” grew. Kanchanjangha’s tea masters now began crafting many types of tea. From high mountain black tea with complex floral notes (i.e. Kanchanjangha Noir), to highly coveted specialty teas from a more premium “one leaf and a bud pluck” (i.e. White Prakash and Kumari Gold). This farm was the first tea farm in Nepal to become organic.

The debate: Indian and Nepali tea

For those who are not aware, there is certain “pecking order” amongst tea producing countries. There are countries who have already claimed a name for their tea (i.e. India’s Darjeeling, Assam, Ceylon tea from Sri Lanka and of course China and Japan) and the rest who come from less well-known tea producing countries and areas. Nepali tea, until recently, belonged to the latter. Tea Rebellion is here to facilitate change!

Why the change?

This imbalance has spurred a debate when it comes to high mountain teas in the region. The Indians claim that the Nepal sells their tea as Darjeeling, using the name recognition of the Indian gardens. Nepal on the other hand, argues that Darjeeling gardens seek out their teas to buffer their volumes (and margins). As usual, there is probably a bit of truth in both stories and, interestingly, they both point to some similarity between the teas.

Our experience:

After having spent amazingly rich and quality time at Kanchanjangha on our immersive tea trip, the rights and wrongs of this debate no longer matter to us. After five days on the farm (including the grueling travel to and from), we are in absolute awe at the immense challenges that were overcome to create Kanchanjangha as it is today. What matters now is that Kanchanjangha has succeeded in creating a tea farming community that puts its people first, while creating teas that are unique and authentic. The farm’s operations allow rural high mountain families to maintain an independent life on their farms away from cities such as Kathmandu, where environmental problems abound and jobs are hard to come by.

Benefits abound:

Social change and transformation in Nepal continue to be at the forefront of this cooperative. The farm is putting all full-time farmer and workers kids through schooling and also has funded cows for the community. These cows are given to one individual who, in return, gives the first calf back so that it can be given to another member (a revolving cow fund as it were!). The cooperative buys the cow manure from the families generating an additional income. Furthermore, the cooperative is helping smallholders in the area to become organic. In addition, they are also building a tea factory which will help achieve better prices by selling a finished product.

Plucking and making tea:

After an hour of plucking in the morning on a very steep hill, we were in absolute awe at our plucking instructors Sukra (supervisor) and Man Maya (master plucker). They taught us not only which two leaves and a bud to pluck, but also how to prune at the same time (harder than the plucking, as the right ‘mother leaf’ must be left intact in order for a new shoot to grow).

We only managed to pluck 2 kg, at most, amongst 3 of us in one hour. We were exhausted from balancing with the basket strapped onto our backs and the steep hill under our feet. After plucking, we headed to the factory and separated our leaves into two categories for withering into:

- Green tea to be finished that same day and,

- Black tea which was to undergo complete oxidization over the next 2 days.

Green tea processing included: withering, kill green, rolling and firing under the supervision of Farm Manager Nira Nanda (NN). By contrast, black tea processing had longer withering of 20 hours, then hand rolling, over night oxidization, and finally firing. Of course the final step was tasting for both teas!

Through this processing it became clear that while big machinery is important to manage sizeable production volumes, it is only a tea masters’ experience that can tell when a certain step is fully complete (i.e. When do the leaves feel dry enough to stop the drying process?).

Today’s challenges:

These days, Kanchanjangha is facing new challenges. The road built from the factory to the top tea gardens urgently needs paving to enable quicker transport of the leaves back to the farm. However, this requires government approval and possibly funding. A paved road would cut down travel time from 1 hour to about 20 minutes. It would also reduce the road getting blocked due to landslides and floods. Furthermore, like most tea farms, Kanchanjangha is suffering labour shortages, which impacts production quantity and quality. While the older generations are used to the hard work and happy to pluck for a whole day, younger rural folks in the high mountain are less keen and there are far less of them compared to before.

Going forward:

Visiting Kanchanjangha has without a doubt been transformative and experiential for us. Making tea from scratch has driven home all of the tea quality aspects and possible pitfalls. Witnessing the social impact of Kanchanjangha has made us very proud to be a trusted partner. Here is to Kanchanjangha, to its amazing origin and to an ever-growing social impact. We are looking forward to working together to help spread the love for its teas and raise funds to create a library and computer lab at the Phidim primary school.

Already hoping we will be able to make it back to Nepal next year…